PRODUCTS

SystemEyes™ – Asset Performance Management

Products

How to have an Industrial IoT program NOW…

With the sensors you already GoT

SystemEyes™ in Action

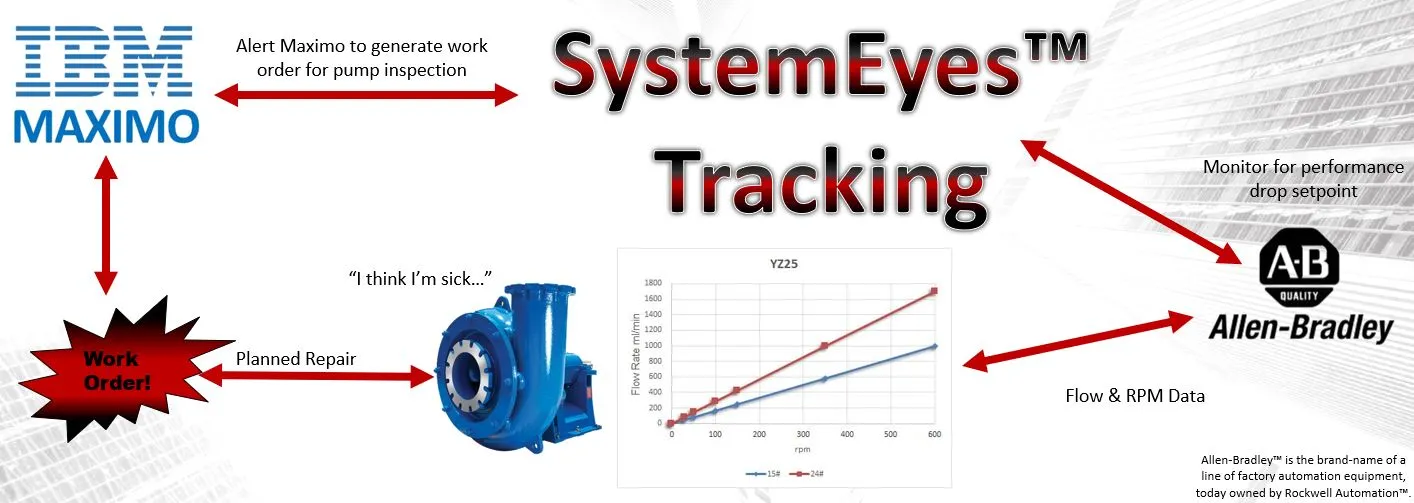

Data from PLCs across the enterprise contain valuable information that can predict otherwise undetectable early failure warnings.

For example, a pump will exhibit a reduction in flow versus rotational speed when it begins to wear out.

We can detect this with SystemEyes™. Tracking failure months before an operator would notice it. It is also possible to create triggers to generate Maximo work orders to check the pump without any user intervention.

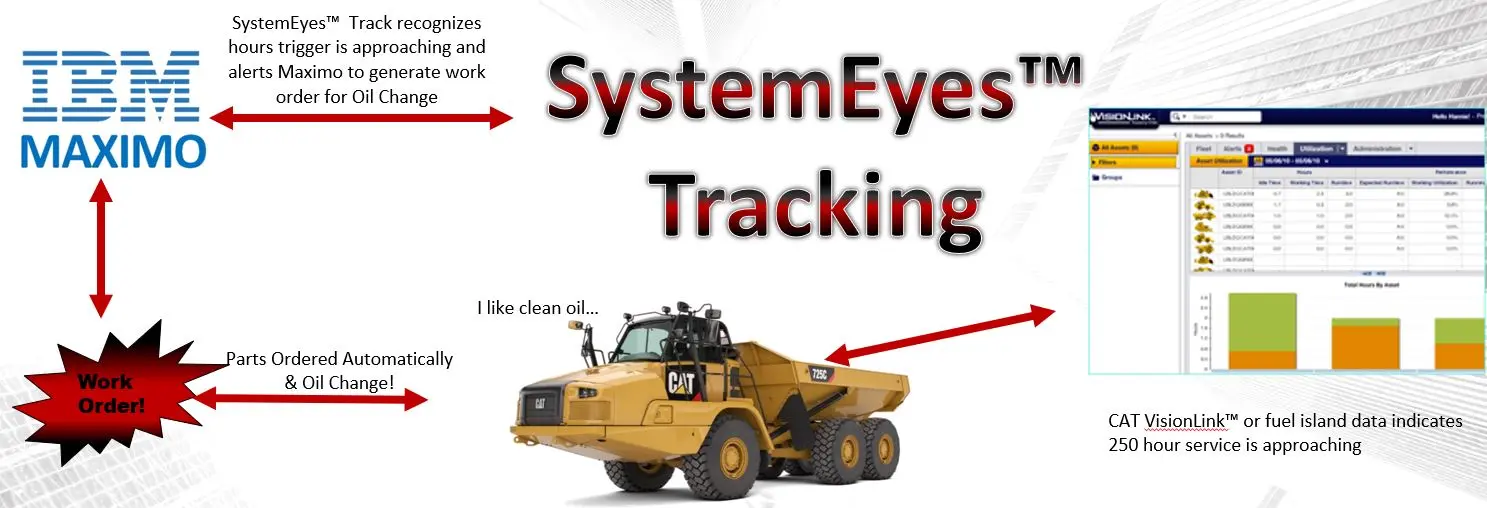

We are able to monitor heavy equipment operating hours and many condition parameters using CAT VisionLink™ telemetry (many already have this).

We can also track hours on machines through the fuel island interface. SystemEyes™ Track can trigger service PMs for the machines based on run-time hours.

Once it does this, Maximo can automatically order the service kit from CAT in time for the repair to occur. Reduced downtime, reduced inventory, and protects machinery from running over warranty limits.

Cat and Caterpillar are registered trademarks of Caterpillar Inc., 100 N.E. Adams, Peoria IL 61629.

Allen-Bradley™ is the brand name of a line of factory automation equipment, owned by Rockwell Automation™.

How our SystemEyes Asset Monitoring Systems work together

As an Organization, you utilize a variety of systems (DCS, PLC, CMMC, etc.). Each system plays a role to support and fulfilling critical needs within the Organization.

However, not one system fulfills all the requirements, and data is compartmentalized within itself.

Instead of implementing new systems that may or may not support all aspects of operations, what if we further developed and connected our current systems to provide a unified platform for reporting, KPIs, operations support, monitoring, and continual improvement?

So what is SystemEyes™?

A bridge to connect your various systems (DCS, PLC, CMMC, CMMS, ERP/EAM) so your Organization can cross the river of inefficiency. Over to a land of improved management and productivity.

SystemEyes™ Asset Performance Management

What does SystemEyes™ Provide?

- Live KPI monitoring

- Asset Tracking

- Remote Asset Management & Remote asset tracking software

- Data Reliability

- On-Demand Reporting

- Increased Visibility of Operational Performance

- Alerts & Suggested Remedies for Equipment Problems

- Increased Productivity

- Decreased Downtime

- Integrated Calculations Using Multiple Sources of Data

- Trigger Work Orders Based on Time Or Condition

SystemEyes™ 20/20 Vision

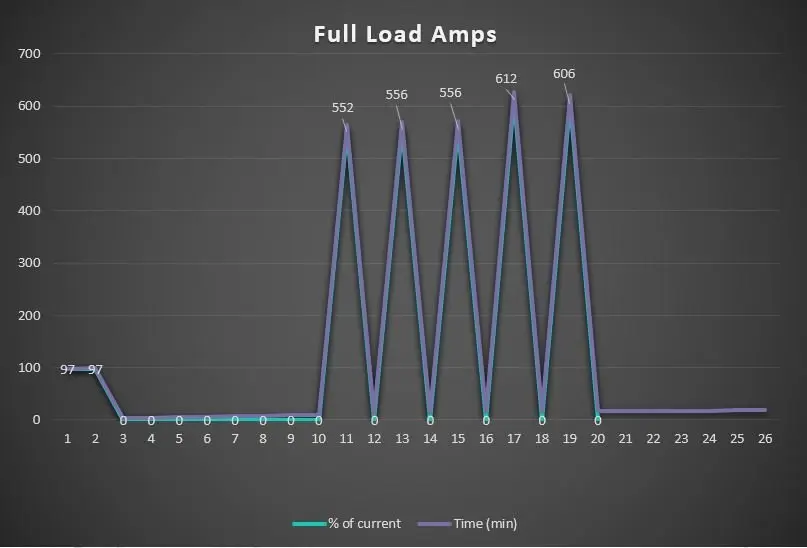

Scenario: Operator hit start on a motor, 5 times within ten minutes. Full Load Amp shutdown was raised by Ops, without knowledge of Maintenance or Engineering

- OEM warranty allows 3 starts per hour.

- Procedure not followed.

- Burned-up motor.

- 48 hours of maintenance downtime

versus 1 hour of Operations time,

Plus costs of replacement assets.

Our brochure that explains more about SystemEyes™ Asset Performance Management