Predictive Maintenance Services

FPA maintenance team can assess how healthy or unhealthy your assets are…

What is Predictive Maintenance?

Predictive maintenance is a type of condition-based maintenance that uses predictive models to estimate when an asset is likely to need maintenance. By using predictive models, predictive maintenance can schedule maintenance activities in advance, before a problem occurs.

Our predictive maintenance strategy can be used on any type of equipment, but it is especially useful for industrial equipment, such as production machinery or vehicles. Our predictive and preventive maintenance can be applied across a wide variety of specialties and industries as an alternative to reactive maintenance plans that create machine downtime and equipment failures.

Predictive maintenance is a valuable tool for any organization that relies on industrial equipment. By using predictive maintenance, organizations can:

- avoid downtime

- reduce the risk of accidents

- increase asset reliability

- improve the efficiency of their operations

- greatly reduce maintenance costs

- prevent equipment failure

Experts in Optimizing Industrial Equipment while reducing Maintenance costs:

We Serve the following vital equipment assets for these industries:

- Steel/Metals/Mining

- Petrol Chemicals

- Building Maintenance

- Food (non-beverage)

- Oil and Gas

- Marine Shipping Docks

What we provide for our clients:

Provide Preventive Maintenance:

A predictive model is used to identify when equipment is likely to need maintenance. This allows for scheduled maintenance before a problem occurs. By utilizing equipment data and ultrasonic technology practices such as vibration analysis we can detect critical asset issues before they arise.

Establish a Predictive Maintenance Program:

We apply our preventive maintenance practices to implement predictive maintenance programs by creating maintenance models to increase ROI for your business. We schedule and help execute predictive maintenance work so you don’t have to. Our predictive maintenance technologies streamline your processes and allow our team to effectively manage your maintenance program.

Condition-based maintenance:

Real-time industrial equipment maintenance is performed when it is needed, based on its current condition. This is in contrast to preventive maintenance, which is performed on a schedule regardless of the equipment’s current condition. Our condition monitoring techniques apply the latest technology including a computerized maintenance management system, condition monitoring sensors, and internet of things (IoT) applications for real time data, monitoring, and collaboration.

Predictive Maintenance Training Programs

Designed for maintenance managers and technicians, teaching them best practices to better analyze data for maintenance, monitor operating conditions, implement a maintenance schedule, and perform maintenance. We will help your team improve asset uptime, data collection, asset performance, and failure predictions.

PROCESS SAFETY MANAGEMENT

PSM, RMP, GMP & SEMS Regulatory Compliance

Safety and environmental compliance are issues at the top of senior management’s mind. Not only is it good practice, but Federal Regulators are taking action to ensure plants are following their mechanical integrity plan with sound predictive maintenance programs.

Some of the “little things” that can make a big difference are:

- Vibration Analysis

- Thermal Imaging

- Electric Motor Testing

- Ultrasonic Detection

- Oil Analysis

If one or more of the above topics is critical to you, FPA has the certified staff to provide those services using world-class predictive maintenance techniques and evaluations.

CONDITION MONITORING FOR PREVENTIVE MAINTENANCE – PdM

FPA is able to help monitor equipment around the clock and ensure it is running properly.

We have several diagnostic and monitoring options available to assist in ensuring the capabilities of your facility. From performing routine vibration analysis to finding leaks and hot spots in your equipment. We also have condition monitoring equipment including; wireless sensors we can set up to monitor equipment 24/7 capable of reporting back as often as 12 seconds getting as close to real time measurements.

Condition Monitoring Services:

- SystemEyes™

- Process Safety Management

- Reliability & Predictive Maintenance Programs

- Thermography

- Ultrasound Detection

- Vibration Analysis

- Electric Motor Evaluation

- Wireless Sensors

FIELD SERVICES

FPA will come on-site and ensure your critical assets are set up and running at their best.

We offer laser alignment for motor shafts and belts during an installation or after a repair. As well as balancing done out in the field for fans, blowers, brush cutters, generators, and other equipment in need.

Field Services:

- Precision Laser Alignment

- Field Balancing

Why Failure Prevention Associates?

Based in Houston, Texas. Our on-site vibration analysis services saves you time and money with less unplanned downtime and lower overall operational costs.

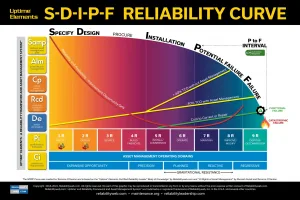

We employ the Uptime Element(C) as a format for Reliability Excellence. We have certified and experienced reliability and condition monitoring analysts who can rapidly deploy to your site and assess the condition of your critical machinery using vibration analysis, electric motor testing, ultrasound detection, thermal imaging, and more.

FPA offers both bad actor troubleshooting and monthly, quarterly, and semi-annual condition monitoring services. This provides cost savings in man hours, time, and profits while obtaining veteran expertise with advanced condition monitoring technology. The time and effort to create and maintain an in-house team can be difficult and time-consuming. Jump-start your program by using our expertise for an immediate ROI.